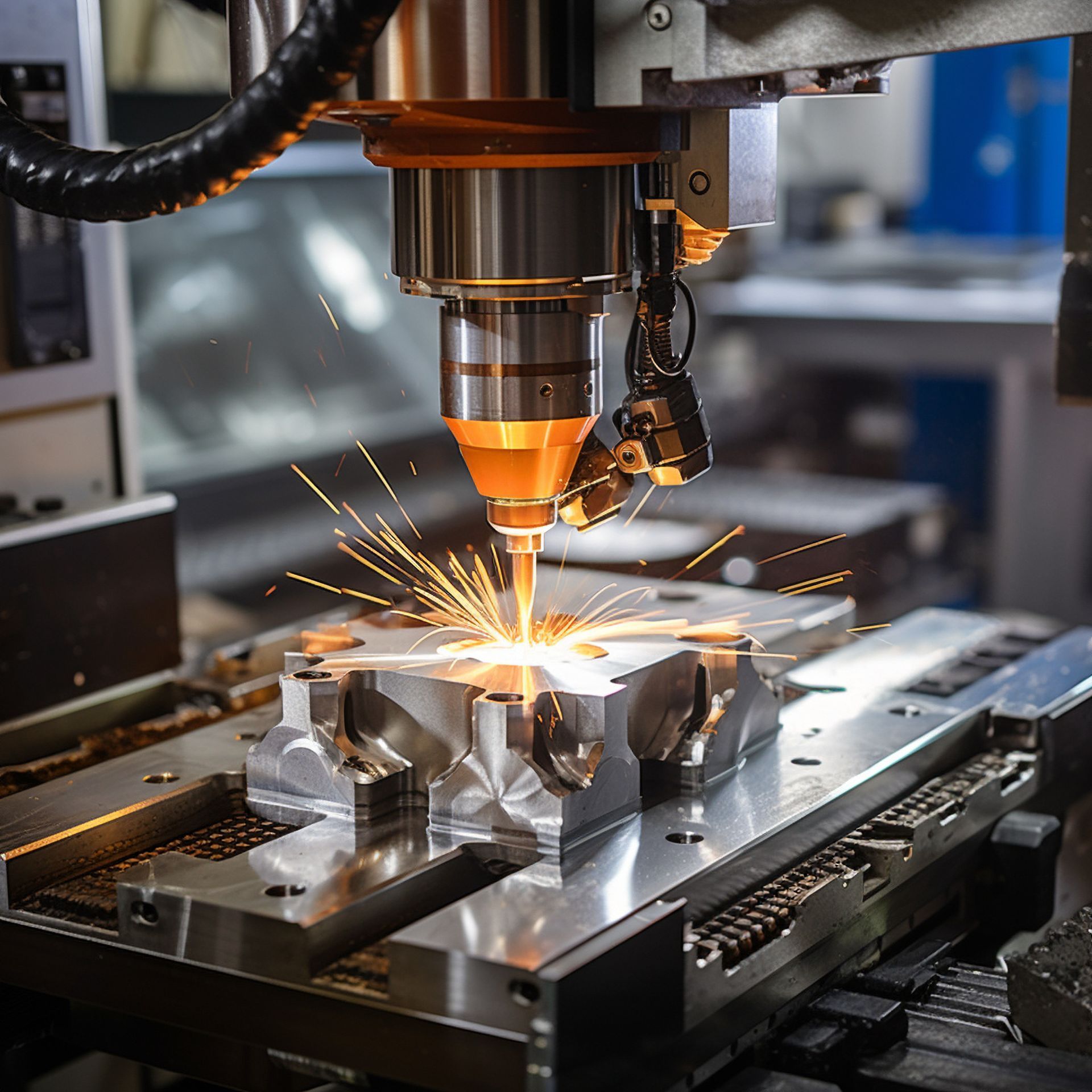

Laser Cutting

At Fabcon Project Group, our laser cutting services enable us to achieve precise and intricate designs, including stainless steel, mild steel, and aluminium, tailored to your specifications. Laser cutting is pivotal in fabricating sheet metal products like architectural facades, offering nearly limitless 2D shapes with exceptional precision and minimal distortion.

Employing computer-aided design (CAD) and computer-aided manufacturing (CAM), we swiftly translate detailed drawings into laser-cutting instructions, ensuring efficient production without compromising quality. With over 25 years of experience, we specialise in aluminium fabrication for industries such as mining, construction, engineering, and manufacturing, consistently delivering superior results that exceed our clients' expectations.

Contact us to discuss your next project!

Providing all-encompassing solutions for residential, commercial, and government projects in NSW, specialising in custom items and handling projects of various scales.